Abstract

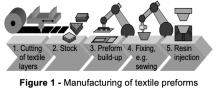

Even though carbon fiber reinforced polymers (CFRP) have outstanding mechanical benefits (low weight, high stability), the manufacturing process is fragile. Small variations in the process result in decreasing mechanical stability and additional production costs. This is especially critical for small lot sizes in which automation is not profitable. Instead, manual processes are required, which are highly prone to variances in process quality. As the quality control within the manual production is quite demanding, an assistance system is needed to guide workers and reduce the variance in product quality. Augmented Reality (AR) applications could be used to support workers during quality control. Yet, no empirical studies of the applicability of AR to support CFRP processing have been carried out. Therefore, we present an AR-based prototypic worker support system for CFRP manufacturing. Empirically, the influence of three different assistance modalities (auditory, visual, combined) and a control condition (no feedback) on quality control were investigated. In addition, the impact of workers’ individual factors on performance was studied. Overall, the combined feedback worked best. Taking user factors and performance into account will provide useful guidelines for the development of a context-adaptive support system.

Ziefle, M., Brauner, P., Vervier, L., Fürtjes, T., Atdorf, L., Schmitt, R., Rossmann, H.-J.: The Effectiveness of Different Types of Context-Adaptive Tutors During Quality Control in Carbon Fiber Reinforced Polymer Production. In: Dimitrov, D. and Oosthuizen, T. (eds.) Proceedings of the 6th International Conference on Competitive Manufacturing 2016 (COMA ’16). pp. 193–198. CIRP, Stellenbosch, South Africa (2016).